Call Us

08045804981Showroom

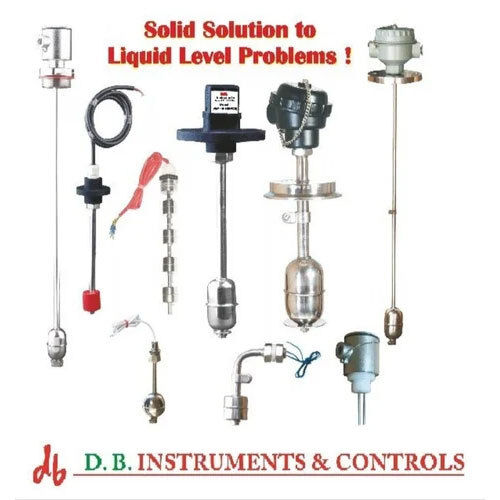

If you need to determine the level of fluid at any specific locations, then install a level switch. This measurement device will quickly detect the presence as a result.

In order to keep a check on the level of fluid in the tank, customers can make use of level transmitter. This measuring device can measure the level of all kinds of fluid, from water, fuel to viscous fluid.

Buy from us level gauges for your chemical, petrochemical and other industrial sectors for indicating the level of the fluid. These devices are made to operate in all kinds of fluid, from harmful to chemically aggressive.

This array of low maintenance Float Switches is used as essential part of filters, heat exchangers, pumps and various other processing systems. These switches are compatible with different media like gas, air and fluid. These switches can be replaced at less cost.

Digital Level Indicators operate by integrating with control panel to inform about exact level of water. These sensor probe based digital indicators are well known for their high precision level, ergonomic look and reasonable price.

Flow Switches are utilized to control flow level of vertical or horizontal pipelines by using triclover paddle. These switches can be used at low flow level. High precision level and PLC controlled mechanism are the main aspects of these switches.

Level Sensors offered by us are well known for their ergonomic look and long lasting quality. These sensors are used for monitoring and maintaining liquid level. Long life span is one of their main aspects.

Rotameters are used for measurement of gas and fluid flow. Accessible in different specifications, these instruments can be availed in acrylic and glass made design choices. Precise measurement is one of their main aspects.

Temperature Transmitters can establish connection with temperature sensor for sending signal while measuring different parameters of water. User friendly design, long life span and reasonable price are their main aspects.

Pressure and Temperature Gauges are used for determining the exact level of fluid and gas transferred at specific force. User friendly mechanism, long functional life and ergonomic look are the key aspects of these instruments.

Level Measurement Instruments are well known for their high accuracy level. Designed by skilled technocrats, these instruments have ergonomic look, user friendly mechanism and long life span. These instruments have reliable operation.

Ultrasonic Transmitters are used for effective transferring of ultrasonic wave meant for communication purpose. Light in weight, these sensor based high performance systems have reverse polarity and over voltage protection function.

We want inquiries from Mumbai and Maharashtra.