Call Us

08045804981Vibrating Fork Level Switch

Price 10500.0 INR/ Piece

Vibrating Fork Level Switch Specification

- Protection Level

- IP65/IP68

- Automation Grade

- Automatic

- Max. Current

- 5A

- Response Time

- <1 second

- Mechanical Life

- > 10 operations

- Temperature Range

- -20C to 80C

- Rated Voltage

- 230V AC / 24V DC

- Circuit Type

- SPDT Relay Output

- Finish Type

- Polished / Matt

- Number of Module

- Single Module

- Product Type

- Vibrating Fork Level Switch

- Material

- S.S / P.P / TEFLON

- Insulation Resistance

- 100 M at 500 VDC

- Contact Resistance

- 50 m

- Max. Voltage

- 230 Volt (V)

- Operating Temperature

- Up to 80 Celsius (oC)

- Size

- Standard/Custom options available

- Color

- Gray

- Weight

- Approx. 0.8 1.5 kg (depending on material)

- Mounting Type

- Screw/Flanged/Threaded

- Current Rating

- 5A @ 230V AC

- No Of Poles

- Single Pole

- Approval/Certification

- CE, ISO certified

- Medium Density

- > 0.7 g/cm³

- Application

- Liquids, slurries, solid detection in tanks/vessels

- Ambient Temperature

- -10°C to 60°C

- Process Connection

- 1" / 1.5" / 2" BSP/NPT

- Output Type

- Relay

- Power Supply

- 230V AC / 24V DC

- Ingress Protection

- IP65 / IP68

- Cable Entry

- PG9 / PG11 / M20 x 1.5

- Sensing Probe Length

- 100 mm standard, optional up to 2500 mm

- Fork Frequency

- Approx. 350 Hz

- Indication

- LED status indicator

- Enclosure Material

- Die-cast Aluminum / Polycarbonate

Vibrating Fork Level Switch Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 7 Days

About Vibrating Fork Level Switch

Advanced Site & Plant Applications

The Vibrating Fork Level Switch excels in diverse site applications, including chemical plants, water treatment facilities, and storage tanks. Perfect for process automation, it handles liquids, slurries, and dry material with precision. Extra features include a radiant LED status indicator, customized sensing probe lengths, and robust mounting options. Its adaptability makes it suitable for challenging environments and critical plant installations.

Packaging, Delivery & Certifications

Each Vibrating Fork Level Switch is carefully packaged to ensure safe freight and timely arrival at your site. With a competitive list price, rapid delivery is guaranteed, typically within 710 days. Every unit is CE and ISO certified, affirming adherence to international quality standards. DB Instruments ensures secure and reliable delivery, supported by stringent packaging protocols for optimal product condition on arrival.

| Maximum Fluid Viscosity | Up to 10,000 cp |

| Max Operating Pressure | 10kg/cm2 |

| Max Operating Temperature | Up to 80 deg C |

| Minimum Fluid Density | Greater than 0.7 gm/cc |

| Power Supply | 230 V AC |

| Country of Origin | Made in India |

| Brand | DB Instruments |

| Mounting Options | Side Mount |

| Media Type | Dry Material |

FAQs of Vibrating Fork Level Switch:

Q: How does the Vibrating Fork Level Switch operate in tanks and vessels?

A: The switch functions by vibrating at approximately 350 Hz; when the fork comes in contact with a medium above 0.7 g/cm, vibration changes, triggering the relay output and LED indication for accurate level detection in tanks and vessels.Q: What are the main benefits of using this level switch in industrial plants?

A: Its top-notch automation, fast response time (<1 second), and radiant durability provide dependable solid and liquid detection, ensuring reliable operation in process control environments such as chemical, water treatment, or storage plants.Q: Where can the Vibrating Fork Level Switch be installed?

A: It can be installed in side mounts of tanks, vessels, or process pipelines, supporting screw, flanged, and threaded connections in 1", 1.5", or 2" BSP/NPT standards, with enclosure protection rated at IP65/IP68.Q: How is the packaging and shipping process ensured for safe delivery?

A: Each unit is securely packaged to withstand freight handling, and shipping is expedited for timely arrival, typically within 710 days. International certifications like CE and ISO guarantee product integrity on arrival.Q: What media types and operating conditions can the switch handle?

A: It is suitable for liquids, slurries, and dry materials, tolerates fluid densities above 0.7 g/cm, viscosities up to 10,000 cp, operating pressures up to 10 kg/cm, and temperatures up to 80C, making it ideal for both harsh and standard industrial conditions.Q: When should users opt for custom probe lengths or materials?

A: Custom options are recommended when specific tank depths, medium properties, or unique installation conditions require adjustment, allowing the switch to be tailored in probe length (up to 2500 mm) and construction material (S.S, P.P, TEFLON).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Level Switches Category

Top Mounted Guided Float Level Switch

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Mounting Type : Top Mounted

Contact Resistance : 100 m

Temperature Range : 10C to 80C

Size : Sizes Available

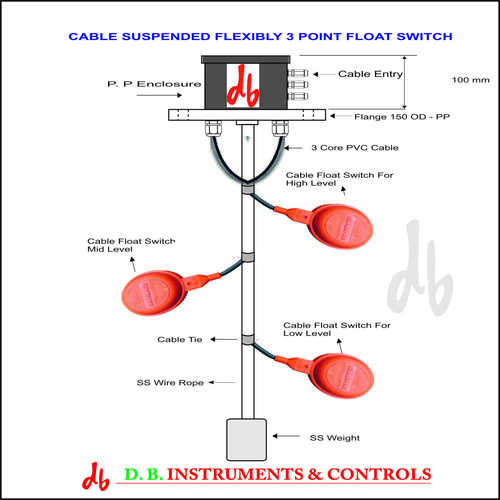

3 Point Flexible Level Switch

Price 9500 INR / Piece

Minimum Order Quantity : 1 Piece

Mounting Type : Cable Suspended / Hanging

Contact Resistance : 50m

Temperature Range : 10C to +80C

Size : Sizes Available

Flame Proof Side Mounted Level Switches

Price 10500 INR / Piece

Minimum Order Quantity : 1 Piece

Mounting Type : Side Mounted

Contact Resistance : Below 100 m

Temperature Range : 10C to 80C

Size : Sizes Available

Capacitance Type Level Switch

Price 19000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Mounting Type : Threaded Mounting, Flanged Mounting

Contact Resistance : 50m

Temperature Range : 20C to +80C

Size : Threaded or Flanged Mounting, Customizable Length

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free