Call Us

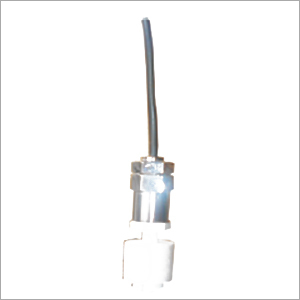

08045804981Capacitance Type Level Switch

Price 19000 INR/ Piece

Capacitance Type Level Switch Specification

- Circuit Type

- SPST or DPDT

- Rated Voltage

- 230VAC/24VDC

- Response Time

- <1 second

- Protection Level

- IP65

- Automation Grade

- Automatic

- Mechanical Life

- Over 1 Million Operations

- Temperature Range

- -20C to +80C

- Number of Module

- Single

- Max. Current

- 5A

- Finish Type

- Powder Coated

- Product Type

- Capacitance Type Level Switch

- Material

- Plastic,Metal

- Insulation Resistance

- 100M at 500VDC

- Contact Resistance

- 50m

- Max. Voltage

- 230 Volt (V)

- Operating Temperature

- -20C to +80C

- Stoke

- No Moving Parts

- Size

- Threaded or Flanged Mounting, Customizable Length

- Color

- Gray

- Weight

- Approx. 300g

- Mounting Type

- Threaded Mounting, Flanged Mounting

- Current Rating

- 5A

- No Of Poles

- Single Pole

Capacitance Type Level Switch Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 1 Week

About Capacitance Type Level Switch

Capacitance Type Level Sensor

- A capacitance is formed between the probe and the vessel wall

- .As the level of the measuring medium rises or falls capacitance

- between the probe and vessel wall changes proportionately.

- high frequency sine wave is applied between the probe and

- tank wall. A change of medium level will induce a change in the

- current of the applied sine wave. From when the

- capacitance in the vessel increase, impedance will decrease

- and current will increase and vice-versa. (Z=Resistance,

- C=Capacitance, F= Frequency)

- Head mounted electronics converts the capacitance variation to 4-20mA signal for long distance

- transmission. It is provided with trimpots for SPAN and ZERO adjustments. With no moving parts

- it is free from wear and tear, rugged and robust in construction. No dead zone like float based instruments.

- It must be ensured that the probe is parallel to the tank wall throughout its length.

Salient Features :

- Two parts isolated design-Electronic Module can be easily separated without removing the probe and

- without necessity of process shut down. So module replacement is easy.

- No moving parts, it is rugged and robust instrument.

- No dead band or dead zone like float based/ultrasonic instruments.

- Suitable for operation from 12 to 32 VDC, with reverse polarity protection.

- Standard output 4-20mA.Voltage output of 0-10 optional. (For 12 V input supply output 0-5V and with 24 V supply output 0-10V).

- Plug and play with reference probe and rod.

- Remote electronics as option with 2 Metre long coaxial cable.

- Standard enclosure weather proof-cast Aluminium or Nylon 66. Flame proof as optional.

- Trim-Pots for span and zero adjustment.

- Our new introduction is Micro processor based Blind Transmitter (available only in weather proof version) with Push Button Teach-in facility and damping arrangement.

Versatile Performance Across Applications

Designed to handle solids, liquids, and slurries, this level switch brings dependable control to diverse industrial operations. The stainless steel probe ensures excellent compatibility, while the customizable mounting and length cater to unique installation requirements. Its ability to function in temperatures from -20C to +80C increases adaptability.

Reliable and Safe Operation

Built with safety in mind, the switch offers short circuit and overload protection. The enclosure, crafted from rugged ABS and polycarbonate, along with IP65 rating, ensures longevity even in harsh environments. With a mechanical life exceeding one million operations, it provides sustained and worry-free service.

Convenient Adjustment and Monitoring

The device features externally adjustable switching points, allowing easy calibration without dismantling. LED indication delivers clear visual status, improving maintenance efficiency. The relay output (SPST or DPDT) and quick response time support immediate and accurate automation decisions.

FAQs of Capacitance Type Level Switch:

Q: How does the Capacitance Type Level Switch detect different substances?

A: This switch utilizes a stainless steel probe to sense changes in capacitance when coming into contact with solids, liquids, or slurries, ensuring reliable level detection across multiple material types.Q: What are the installation options for this level switch?

A: It offers flexible installation through either threaded (1" BSP) or flanged mounting, and the sensing probe length can be customized to suit specific tank or vessel requirements.Q: When should I adjust the switching point, and how is it done?

A: Switching points should be adjusted during installation or when process parameters change. External adjustment is provided, so you can calibrate the switch without opening the enclosure, ensuring convenience and safety.Q: Where can the Capacitance Level Switch be used?

A: It is suitable for use in industrial environments for monitoring levels of solids, liquids, and slurries. Applications include manufacturing plants, chemical processing, water treatment, and food industries across India and global markets.Q: What benefits does the relay output provide?

A: The relay output (SPST or DPDT) allows seamless integration into automation systems, providing reliable on/off signals for alarms, pumps, and control circuits with a fast response time (<1 second).Q: How is safety ensured in this device during operation?

A: Safety is maintained through built-in short circuit and overload protection, robust enclosure materials, and compliance with IP65 protection standards, safeguarding both the device and connected processes.Q: What maintenance is required for optimal performance?

A: Routine visual inspection and testing of the LED indicator, occasional cleaning of the probe, and checking of cable entries (PG11/PG13.5) help ensure continued accurate operation with minimal downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Level Switches Category

Dosing Level Switch

Price 1550 INR / Piece

Minimum Order Quantity : 1 Piece

Max. Voltage : 300 Volt (V)

Product Type : Dosing Level Switch

Color : White

Material : Stainless Steel

90 Degree Level Switch

Price 1200 INR / Piece

Minimum Order Quantity : 1 Piece

Max. Voltage : 300 Volt (V)

Product Type : Top Mounted 90 Degree Level Switch

Color : Gray

Material : Metal & Plastic

Bilge Water Level Switches

Price 8500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Max. Voltage : 220 Volt (V)

Product Type : Bilge Water Level Switches

Color : Gray

Material : Stainless Steel

Conductivity Type Level Switch

Price 4000 INR / Piece

Minimum Order Quantity : 10 Pieces

Max. Voltage : 220 Volt (V)

Product Type : Conductivity Type Level Switch

Color : Gray

Material : Stainless Steel

Send Inquiry

Send Inquiry