Call Us

08045804981Electronic Control Units

Price 3500 INR/ Piece

Electronic Control Units Specification

- Mounting Type

- DIN Rail Mount

- Frequency

- 50/60 Hz

- IP Rating

- IP65

- Display

- LED Screen

- Protection Level

- IP65

- Sensor Type

- Integrated Sensors

- Output

- Relay/Transistor

- Pole Type

- Single/Double

- Features

- High Reliability, Compact Design

- Current

- 10A

- Usage & Applications

- Process Control, Automation Systems

- Installation Type

- Panel Mount

- Measuring Range

- 0-10 Bar

- Phase

- Single/Three Phase

- Connectivity Type

- RS-485, CAN Bus

- Switch Type

- Electronic Switch

- Product Type

- Electronic Control Units

- Operating Temperature

- -20C to 60C

- Working Temperature

- -10C to 50C

- Input

- Analog/Digital

- Pressure Type

- Absolute, Gauge

- Diameter

- Standard Size

- Application

- Industrial

- Supply Voltage

- 220-240 Volt (v)

- Accuracy

- 1%

- Dimension (L*W*H)

- 160mm x 120mm x 60mm

- Weight

- 1.2 Kg

- Warranty

- 1 Year

Electronic Control Units Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 1 Week

About Electronic Control Units

Product details

- Display : 0.5" Seven Segment LED,3 1/2" or 4 digits.

- Input Signal : 4 to 20 mA

- Mains Power Supply : 230 VAC /12 or 24 VDC

- Mounting : Flush Panel

- No of Set Points : 2

- Overall Dimension : 96 x 96 x 110 mm

- Set Point Adjustment : Push Button / Potentiometer

- Country of Origin : Made in India

- Brand : DB Instruments

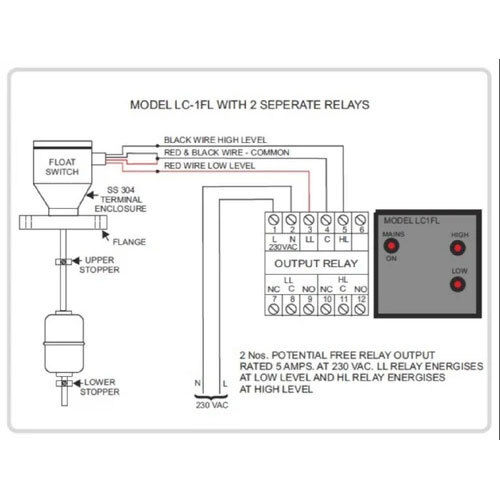

- Model No : MLC-03,MLI-144,LC1FL,LC2FL,MLC-04

- Mounting Type : Wall Mount,Panel Mount,DIN Rail Mount

Built for Industrial Demands

Designed to withstand tough industrial environments, this Electronic Control Unit features IP65-rated ABS plastic housing to shield against dust and moisture. Its robust design and panel/DIN rail mounting enable seamless integration into existing systems. Reliable performance is further reinforced by automatic temperature compensation and operation across wide temperature and humidity ranges.

Precision and Connectivity

With integrated sensors measuring 0-10 Bar (absolute and gauge pressure) at 1% accuracy, our ECU ensures precise monitoring. It supports both relay and transistor outputs, RS-485 and CAN Bus communication, and is compatible with Modbus and Profibus protocols, facilitating flexible, real-time automation across diverse industrial networks.

FAQs of Electronic Control Units:

Q: How do I install the Electronic Control Unit in my industrial process control system?

A: You can install the ECU using either panel mount or DIN rail mount methods, which are suitable for standard industrial setups. Follow the manufacturers instructions to ensure correct wiring of analog/digital inputs and secure integration into your automation system.Q: What are the benefits of automatic temperature compensation in this unit?

A: Automatic temperature compensation ensures that pressure and other sensor readings remain accurate despite fluctuations in ambient temperature, maintaining precision and reliability for critical industrial processes.Q: When should I use the data logging feature on the ECU?

A: The data logging capability is ideal for monitoring process parameters over time, performing trend analysis, or meeting compliance requirements. You should activate data logging when historical performance data is needed for diagnostics or audits.Q: Where can the Electronic Control Unit be deployed given its protection and enclosure features?

A: Thanks to its IP65-rated ABS plastic enclosure, the ECU is suitable for deployment in environments where exposure to dust, moisture, and high humidity is likely, such as manufacturing plants, automation lines, and process control rooms.Q: What communication protocols are supported, and how do they enhance connectivity?

A: This ECU supports Modbus and Profibus protocols over RS-485 and CAN Bus connectivity types. These industry-standard protocols facilitate seamless networking with PLCs, sensors, and other control devices, ensuring reliable data exchange and system integration.Q: How does the integrated display contribute to usability?

A: The 128x64 pixel LED screen provides clear and immediate feedback on current measurements and system status, simplifying monitoring and allowing for quick decisions based on real-time data.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electronic Control Units Category

DLI 144 ECU

Price 8500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50 Hertz (HZ)

Supply Voltage : 220440 Volt (v)

Application : Commercial

Warranty : 1 Year

DLc1fl-2sr Electronic Control Unit

Price 3500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50 Hertz (HZ)

Supply Voltage : 230 Volt (v)

Application : Industrial

Warranty : 1 Year

MLC 03 Electronic Control Unit

Price 3500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50 Hertz (HZ)

Supply Voltage : 230 Volt (v)

Application : Industrial

Warranty : 1 Year

Flush Mounted Panel Model DLC1 FL

Price 3950.0 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50 Hertz (HZ)

Supply Voltage : 230 Volt (v)

Application : Industrial

Warranty : 1 Year

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free