Call Us

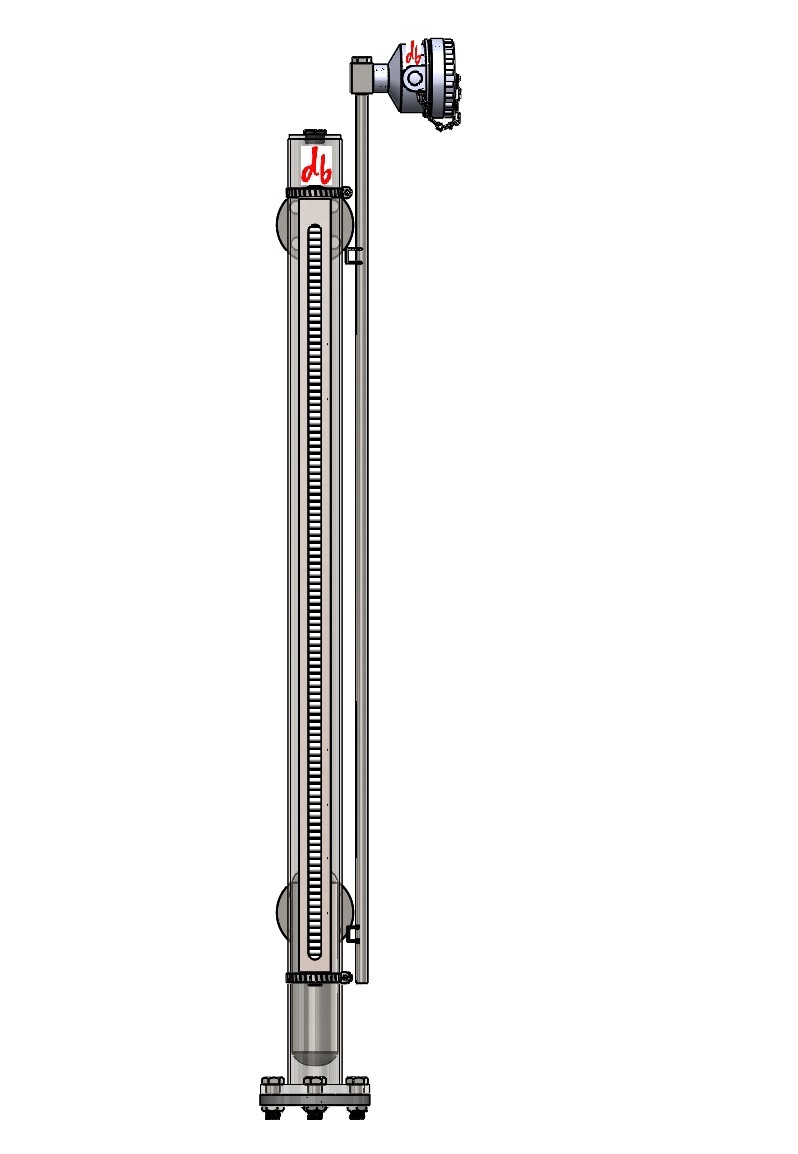

08045804981Level Gauge With Transmitter

Price 18500 INR/ Unit

Level Gauge With Transmitter Specification

- IP Rating

- IP65 / IP67

- Protection Level

- IP65 / IP67

- Installation Type

- Top / Side Mounted

- Measuring Range

- 0.3 m to 5 m

- Features

- Corrosion resistant, Robust construction, Wide measuring range, Easy installation

- Usage & Applications

- Level monitoring for liquids in industrial tanks and vessels

- Sensor Type

- Magnetic Float / Reed Switch

- Output

- Analog / Digital 4-20 mA

- Frequency

- 50 Hertz (HZ)

- Switch Type

- Magnetic

- Display

- Digital/Analog as per model

- Pole Type

- Single / Multi-pole

- Current

- 4-20 mA

- Phase

- Single Phase

- Mounting Type

- Flanged / Threaded / Customized

- Connectivity Type

- 2-wire / 3-wire

- Product Type

- Level Gauge With Transmitter

- Operating Temperature

- -20C to +80C

- Working Temperature

- Up to 80C

- Input

- Float Displacement

- Pressure Type

- Atmospheric / Pressurized

- Diameter

- Typically 1 to 2, Customizable

- Application

- Industrial

- Supply Voltage

- 100 Volt (v)

- Accuracy

- 1% of F.S.

- Dimension (L*W*H)

- Customized as per tank/requirement

- Weight

- As per length/design

- Warranty

- 1 Year

- Ambient Temperature Range

- -10°C to +50°C

- Electrical Connection

- Terminal block / Plug & socket

- Cable Entry

- M20 x 1.5 / 1/2" NPT

- Tank Type Compatibility

- Open or Pressurized Vessels

- Explosion Proof

- Available on request

- Response Time

- <2 seconds

- Material of Construction

- Stainless Steel / PP / PVC

- Output Signal

- 4-20 mA / HART (Optional)

- Process Connection

- Flanged (ANSI/DIN), Threaded BSP/NPT

- Wetted Parts

- SS304 / SS316 / PTFE Coated

- Float Size

- Custom as per liquid/requirement

Level Gauge With Transmitter Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Level Gauge With Transmitter

Magnetic Level Gaugeis a most reliable type of instrument where the direct level measuring is required.We can be provied it with level transmitter aslo.

Features:

- Construction material SS.

- Easy mounting with (Customised) flanged connection

- Low maintenance coast.

- Continuous level monitoring (with use of transmitter 4-20mA output)

- Direct visible level indication in PLC or Controller.

- Safe for corrosive,toxic,flammable liquids.

- Available in different range & types of materials.

- No process fluid in contact with the level indicator.

- Economical measurement solution.

- Safe for high temperature, high pressure applications.

- Perfact level indication without power supply.

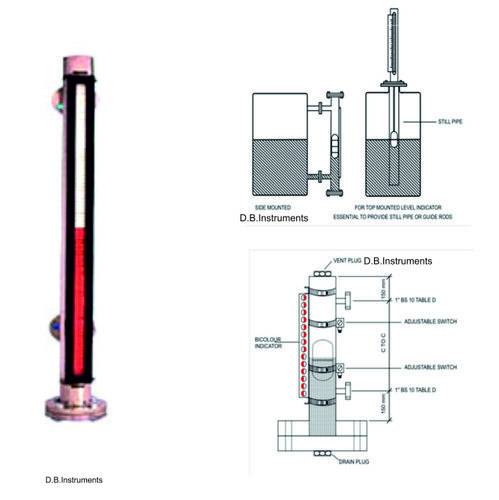

Available in following types:

- With customized length and process connection.

- Bicolour flapperType / Capsule type

- Top Mount Type / Dipstick type.

- Side mount type.

- with in built Transmitter

- with adjustable switch.

Product details

|

Float Chamber Pipe |

2" or 2.1/2" NB |

|

Roller Pivot |

Delrin Bush |

|

Brand |

D B Instruments |

|

Glass Material |

Acrylic |

|

Material |

Stainless Steel |

Versatile Design for Demanding Applications

Crafted to withstand a wide range of operating temperatures (-20C to +80C) and pressures, this level gauge is ideal for monitoring corrosive, viscous, or hazardous liquids. Its construction from stainless steel, PP, or PVC adapts to diverse chemical compatibilities, while available explosion-proof configurations support installation in hazardous areas. The gauge is suitable for both atmospheric and pressurized tanks.

Flexible Mounting and Customization Options

Available with flanged or threaded process connections and customizable dimensions, this transmitter is designed for both top and side mounting. The cable entry is adaptable to M20 x 1.5 or 1/2" NPT, ensuring easy electrical integration. Users can select from a variety of float sizes and materials to match their process needs, ensuring precision measurement and compatibility.

Advanced Output and Display Features

Equipped with either digital or analog display options and 4-20 mA or HART output, this level gauge supports seamless integration with control systems. Its fast response time and 1% accuracy guarantee reliable real-time monitoring, enhancing process visibility and operational safety for industrial users.

FAQs of Level Gauge With Transmitter:

Q: How does the level gauge with transmitter measure liquid levels in tanks?

A: The gauge uses a magnetic float and reed switch technology. As the liquid level rises or falls, the float moves accordingly, altering the reed switch position. This change generates a corresponding 4-20 mA or HART signal, accurately representing the fluid level for remote monitoring.Q: What types of tanks and vessels is this gauge suitable for?

A: This level gauge works with both open and pressurized vessels, making it ideal for most industrial applications such as chemical storage, process tanks, or utility water systems. Its robust construction and adaptable installation allow use in a broad range of industrial tank setups.Q: When is explosion-proof protection recommended for this transmitter?

A: Explosion-proof configurations are recommended for installations in hazardous areas with flammable gases or combustibles. This ensures safe operation and compliance with industrial safety standards. Explosion-proof variants are available upon request to meet site-specific requirements.Q: Where should the level transmitter be mounted for optimal performance?

A: The transmitter can be installed either on the top or side of the tank, depending on tank design and space availability. Flanged or threaded connections (ANSI/DIN, BSP/NPT) provide secure mounting options and minimize the risk of leaks.Q: What are the main benefits of using this level gauge in industrial applications?

A: Benefits include corrosion resistance, customizable configuration, rapid response time (<2s), high accuracy (1% F.S.), and easy integration with existing systems via analog or digital outputs. The units rugged construction ensures long service life and low maintenance needs, even in challenging environments.Q: How is the device installed and connected electrically?

A: Installation is straightforward with flanged or threaded process connections and top or side mounting options. Electrical wiring is facilitated by terminal block or plug & socket connections, and the cable entry supports both M20 x 1.5 and 1/2" NPT standards for versatile site compatibility.Q: What is the typical warranty and after-sales support provided?

A: The level gauge with transmitter comes with a standard 1-year warranty. Manufacturer and supplier support is available across India, ensuring prompt service and reliable after-sales assistance for troubleshooting and maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Digital Level Indicators Category

LED Type Level Indicator

Price 20500 INR / Unit

Minimum Order Quantity : 5 Units

Installation Type : Panel Mount

Measuring Range : Up to 5 meters

Accuracy : 2% of Full Scale

Protection Level : Other, Overvoltage & Reverse Polarity

Side Mounted Magnetic Level Indicator

Price 18500 INR / Unit

Minimum Order Quantity : 1 Unit

Installation Type : Side Mounted

Measuring Range : 300 mm to 5000 mm

Accuracy : 5 mm or better

Protection Level : Other, IP65 or better (with housing)

Magnetic Level Indicator

Price 19500 INR / Unit

Minimum Order Quantity : 1 Unit

Installation Type : Mounted on tank/vessel

Measuring Range : Depends on tank size and configuration

Accuracy : Not available

Protection Level : External enclosure if required, Other

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free