Call Us

08045804981Side Mounted Microswitch Operated Level Switch

Price 3950 INR/ Piece

Side Mounted Microswitch Operated Level Switch Specification

- Temperature Range

- -10C to 80C

- Finish Type

- Polished Stainless Steel

- Automation Grade

- Automatic

- Number of Module

- 1

- Circuit Type

- SPDT

- Response Time

- < 10 ms

- Rated Voltage

- 250V AC

- Protection Level

- IP65

- Mechanical Life

- >1,000,000 operations

- Max. Current

- 5A

- Product Type

- Side Mounted Microswitch Operated Level Switch

- Material

- Stainless Steel

- Insulation Resistance

- 100 M at 500 VDC

- Contact Resistance

- 50 m

- Max. Voltage

- 250V AC

- Operating Temperature

- -10C to 80C

- Stoke

- 2 mm

- Size

- Sizes Available

- Color

- Gray

- Weight

- Approx. 250-400g

- Mounting Type

- Side Mounted

- Current Rating

- 5A

- No Of Poles

- Single Pole

Side Mounted Microswitch Operated Level Switch Trade Information

- Minimum Order Quantity

- 5 Pieces

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 2-4 Days

About Side Mounted Microswitch Operated Level Switch

Side Mounted Microswitch Operated Level SwitchPrinciple of Operation :

Model MLS -16

magnetic level switches work on the principle of magnetic repulsion and therefore they are glandless inside the switch housing which in turn operates an SPDT microswitch. Microswitch contacts can be utilized for initiating audio-visual signals or pump control.

Salient Features :

- As our switches work on magnetic repulsion principle, they are glandless and leak proof.

- No power consumption.

- Internal switch assembly bracket is of cast aluminium.

- Practically no maintenance is required except periodic cleaning.

- Maximum working temperature 250 degree C. (Process Temperature)

- No of contacts : 1 change over as standard. Optional - 2 change over

- For high temperature upto 350C (Process temperature)

- 1 number SPDT reed switch with current rating 100 VA, max switching current 5 Amps, max switching Gravity : Down to 0.75

Caution :

- Level Switches should not be used for direct starting / stopping of pumps. An external relay or contractor must always be used with the level switch.

- MLS-16 side mounted level switches must always be mounted horizontally with outgoing cable entry facing downwards.

- In case of high temperature Model MLS-04-92 HT/MLS-16-92HT and Low Temperature Models

- SMT-16-F82 and SMT-16-F92 arc suppressors/current limiting bias resistor must be provided depending on the load viz inductive or lamp load etc. to reduce the deteriorating effect of contacts due to surge voltages and high in-rush current.

Dimension Models :

- (MLS - 16 - F 82) & (MLS - 16 - F 92 )

- L = 165 mm g=80 mm, with d =49 mm f float

- *Application only for model MLS-04/16 F92, When 62 mm dia float is used L = 240 mm g=135 mm wuth d = 62 mm f

- All dimensions are in millimeter (Tolerance -+/-2mm)

- Model (MLS-16-F82) or (MLS-16-F92S) side mounted magnetic Level Switch.Process neoprene gromet. Supplied with 1.5 Metre long 3-core PVC Cable.

- NB : In case of Model MLS-16-F92 flange size shall be 120 mm dia round flange with 4 bolt holes of 14 mm on 92 PCD.

Optional :

- Adjustable differential upto approx-250 mm

- With 2 microswitches i.e., 2NO + 2NC

Versatile and Durable Level Sensing Solution

Designed for multiple industries including chemical, oil, water treatment, and more, this float-operated, side-mounted level switch combines versatility with long-lasting stainless steel construction. Its snap-action micro switch and changeover contacts ensure reliable switching even in demanding applications, while the polished stainless steel finish maintains resistance against corrosion and harsh liquids.

Easy Installation and Maintenance

Featuring a standard 1" BSP mounting thread, installation is straightforward on most tank designs. The device requires minimal maintenance due to its robust enclosure and high-grade stainless steel float. With a single-pole design and 3-core PVC cable wiring, both setup and troubleshooting are simplified, resulting in reduced downtime for industrial operations.

Reliable Operation and Safety

Engineered to operate efficiently within a wide temperature range (-10C to 80C) and high humidity (95% RH), this microswitch level switch offers insulation resistance of 100 M at 500 VDC and a protection level of IP65. Its rapid response time (<10 ms) and high vibration tolerance make it ideal for automated systems needing trustworthy liquid level indication.

FAQs of Side Mounted Microswitch Operated Level Switch:

Q: How is the side-mounted microswitch operated level switch installed on a tank?

A: The switch is installed through a standard 1" BSP threaded connection on the side wall of a tank. It is secured in place so that the float is positioned inside the tank and can move freely to detect changes in liquid level.Q: What types of liquids or environments is this level switch suitable for?

A: This level switch is suitable for a wide range of liquids including water, oil, and many chemicals. Its SS 316 float and ABS/SS enclosure ensure resistance against corrosion and harsh industrial environments.Q: When should I choose a float-operated, microswitch level switch over other types?

A: Choose this float-operated, microswitch type when you require reliable, precise level detection, fast response, and the ability to handle varying temperatures, humidity, and vibrations. It is ideal for automation in industries demanding robust switching and long-term durability.Q: Where can this level switch be used for optimal benefit?

A: This level switch performs best in industrial tanks and vessels found in sectors such as chemical processing, water treatment, and oil storage, providing efficient and accurate liquid level sensing.Q: What is the process for wiring this level switch?

A: The device comes with a 3-core PVC cable and SPDT (Single Pole Double Throw) circuit, featuring changeover (NO+NC) contacts. Wiring involves connecting the cables cores to your monitoring or control panel according to the required switching logic.Q: How does the snap action switch type benefit liquid level detection?

A: The snap action mechanism ensures rapid and reliable switching as soon as the float actuates the microswitch, minimizing contact wear and ensuring consistent performance for over 1,000,000 operations.Q: What safety and performance features does this level switch offer?

A: It offers IP65 protection against dust and water, high insulation resistance, a mechanical life exceeding a million cycles, and operates safely at up to 250V AC and 5A, making it a dependable choice for automated industrial systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Level Switches Category

Industrial Pressure Transducer

Price 350.00 INR / Piece

Minimum Order Quantity : 1 Piece

Max. Voltage : 30V DC

Product Type : Pressure Transducer

Material : Plastic,Metal

Size : Sizes Available

Top Mounted Liquid Level Switch

Price 3450 INR / Piece

Minimum Order Quantity : 1 Piece

Max. Voltage : 300 Volt (V)

Product Type : Top Mounted Liquid Level Switch

Material : Stainless Steel

Size : Sizes Available

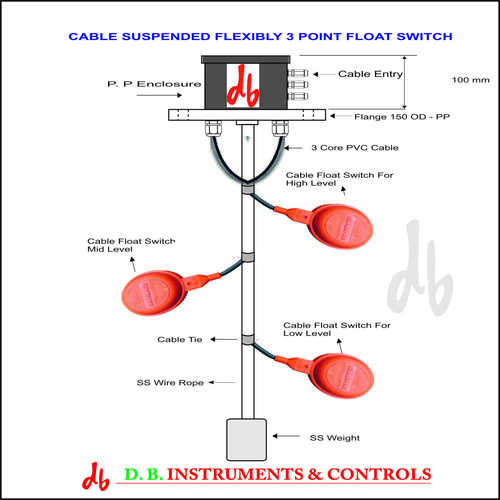

3 Point Flexible Level Switch

Price 9500 INR / Piece

Minimum Order Quantity : 1 Piece

Max. Voltage : 250V AC/DC

Product Type : 3 Point Flexible Level Switch

Material : Plastic,Metal

Size : Sizes Available

Conductivity Type Level Switch

Price 4000 INR / Piece

Minimum Order Quantity : 10 Pieces

Max. Voltage : 220 Volt (V)

Product Type : Conductivity Type Level Switch

Material : Stainless Steel

Size : Custom (as per application)

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free